ThyssenKrupp Aerospace UK, Milton Keynes

Tamlite Lighting boosts lighting quality and reliability for UK Thyssenkrupp site.

The Milton Keynes facility, operated by the multinational industrial group, has been equipped with a host of the latest high-efficiency LED lighting systems.

ThyssenKrupp Aerospace UK is one of the world’s most prominent diversified industrial groups. It has interests in steel production as well as manufacturing ranging from elevators to high-speed trains. They are based in Duisburg and Essen in Germany but have locations in countries around the world. Thyssenkrupp’s operations in the UK include a site in Milton Keynes that delivers products for the aerospace industry.

Improving working conditions and energy efficiency are ongoing priorities. It was for this reason that Tamlite Lighting was chosen to complete an extensive lighting upgrade at the Milton Keynes site. The project was instigated due to inadequate illumination in some areas and an overarching wish to reduce energy expenditure.

“In the narrow stock aisles the lighting was insufficient. There were also replacement and maintenance issues stemming from the older fluorescent fittings,” explains Nathan Blanks, Health & Safety and Facilities Manager. “We also wanted to reduce our environmental impact and benefit from the energy savings that we were aware would result from switching to the latest generation LEDs.”

Energy-saving luminaires

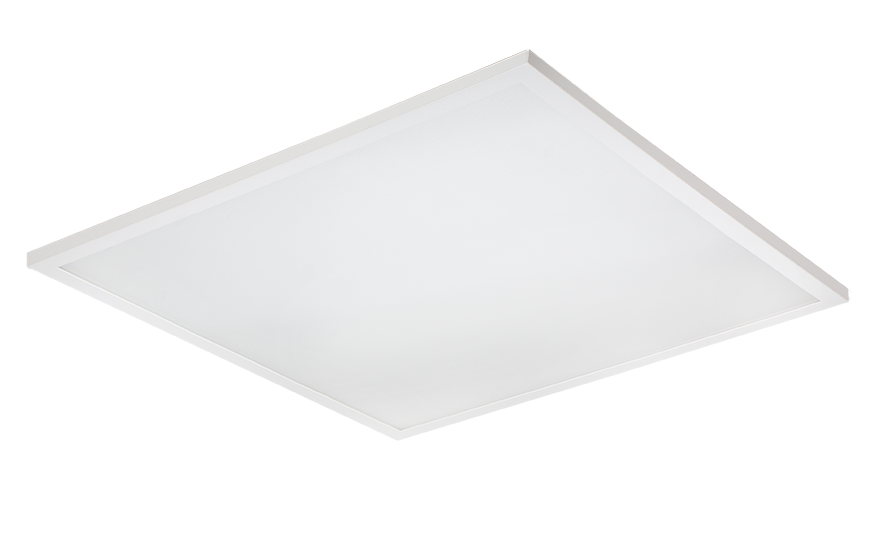

Installing the Tamlite MODLED LG, with up to 125 lumens per Watt efficacy, Thyssenkrupp continue to make significant energy savings.

Electrical Wholesaler CEF had been working alongside Thyssenkrupp to manage the project. Tamlite Lighting was soon engaged to work on the project due to CEF's successful association with the lighting manufacturer. Tamlite specified and provided LED lighting for the earmarked areas. Their expert design team also recommended the installation of sensors to minimise unnecessary illumination.

The Tamlite MODLED LG fittings were supplied for the office areas. These recessed panels are fitted with I-Tech low glare diffuser optics. This ensured that office areas could be sufficiently illuminated without producing intrusive light, allowing workers to be more comfortable and productive.

‘Impressive improvement’

“The replacement of the older fluorescent tubes was particularly welcome,” said Blanks. “There had been issues with some of them for a while, such as flickering. We knew that shifting to LED would eliminate this inconsistency as well as ensuring that replacement/maintenance costs in the future would be considerably lower. This is thanks to the reliability and long-life expectancy of LED lighting.”

Tamlite and CEF worked in close cooperation with Thyssenkrupp’s own team of in-house electricians to ensure that the installation went as smoothly as possible. The end-result has brought about a dramatic upturn in lighting quality.

“The staff are extremely happy with the impressive improvement in the lighting conditions and are particularly pleased that the flickering is a thing of the past!” said Blanks. “The narrow stock aisles are now much brighter and more easily navigable, while the lighting in the office areas is also more consistent."

A development that has been shown to contribute positively to staff well-being and productivity in different industrial sectors.

Blanks also reports that although detailed energy saving data is not yet available and initial results suggest that the targets for the new installation are looking very achievable.